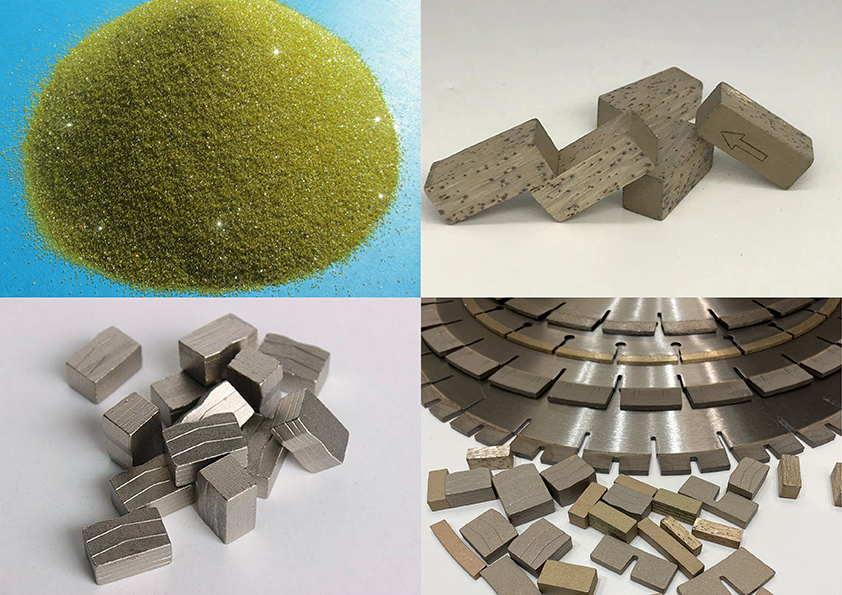

1.Dab tsi yog lub luag haujlwm ntawm txhua qhov khoom hauv lub pob zeb diamond pom hniav pob zeb levrix binder?

Lub luag hauj lwm ntawm tooj liab: tooj liab thiab tooj liab raws li alloys yog cov khoom siv feem ntau siv hauv cov hlau khi pob zeb diamond cov cuab yeej, nrog electrolytic tooj liab hmoov yog feem ntau siv.Tooj liab thiab tooj liab ua alloys yog li dav siv vim tias qhov kev ua kom txaus siab rau cov khoom siv tooj liab, qhov kev ua kom zoo thiab kev ua haujlwm ua haujlwm nrog lwm cov ntsiab lus.Txawm hais tias tooj liab pob zeb diamond diamonds, qee cov ntsiab thiab cov tshuab liab tuaj yeem txhim kho lawv cov wettability rau pob zeb diamond.Ib qho ntawm cov khoom xws li CR, TI, W, Qhov twg tooj liab thiab carbides tuaj yeem siv los ua cov liab alloys alloys ntawm pob zeb diamond.Lub solubility ntawm tooj liab hauv cov hlau tsis siab.Yog tias muaj tus tooj liab ntau dhau ntawm cov hlau, nws tau txo qis cov kev ua haujlwm tshav kub thiab ua rau cov khoom tawg.Tooj liab tuaj yeem tsim cov kev daws teeb meem nrog npib tsib xee, cobalt, manganese, Tin, thiab zinc, ntxiv dag zog rau cov matrix.

Txoj haujlwm ntawm Tin: tin yog ib qho kev txo qis ntawm cov kua av alloys thiab muaj cov txiaj ntsig ntawm kev txo lub chaw ntub dej ntawm cov kua alloys ntawm pob zeb diamond.Nws yog ib qho khoom uas txhim kho cov ntub dej ntawm cov hlau ua hlau, txo lub suab me yaj ntawm alloys, thiab txhim kho qhov muaj peev xwm ntawm kev nias.Yog li sn tau dav siv nyob rau hauv cov nplaum, tab sis nws siv yog txwv vim nws qhov loj nthuav dav coefficient.

Lub luag hauj lwm ntawm Zinc: hauv cov cuab yeej pob zeb diamond, ZN muaj ntau yam sib xws, thaum Zn tsis zoo thaum hloov chaw ntawm pob zeb diamond ntawm pob zeb diamond ntawm pob zeb diamond.Lub vapor siab ntawm hlau ZN yog qhov siab heev thiab nws yog qhov yooj yim los ua pa roj, yog li nws yog ib qho tseem ceeb kom them sai sai rau tus nqi ntawm ZN siv Binders.

Lub luag haujlwm ntawm txhuas: Hlau txhuas yog lub teeb pom kev zoo heev thiab deoxidization zoo.Thaum 800 ℃, lub kaum pob zeb ntub ntawm ib qho ntawm pob zeb diamond yog 75 °, thiab ntawm 1000, lub kaum sab xis yog 10 °.Ntxiv txhuas hmoov rau lub hnab ris ntawm cov cuab yeej pob zeb diamond tuaj yeem tsim cov theem carbide ti Å alc thiab intermetallic compound tial nyob rau hauv matrix alloy.

Lub luag haujlwm ntawm cov hlau: hlau muaj lub luag haujlwm ntau dua hauv phau ntawv, ib yog rau Carburized carbides nrog cov pob zeb diamond, thiab lwm yam yog rau lwm cov los txhawb nqa lub matrix.Lub siab tawv ntawm cov hlau thiab pob zeb diamond yog qhov zoo dua li ntawm tooj liab thiab txhuas, thiab cov nplaum ua haujlwm ntawm cov hlau thiab pob zeb diamond yog siab dua li ntawm kev cobalt.Thaum muaj cov pa roj carbon tsim nyog yog yaj nyob rau Fe raws li alloys, nws yuav tau txais txiaj ntsig rau lawv txoj kev sib txuas nrog pob zeb diamond.Nruab nrab etching pob zeb diamond los ntawm Fe raws Alloys tuaj yeem nce cov quab yuam sib raug zoo ntawm qhov sib khi thiab pob zeb diamond.Lub pob txha tawv tsis du thiab liab qab, tab sis npog los ntawm ib txheej ntawm alloy, uas yog lub cim ntawm txhim kho kev sib raug zoo.

Lub luag haujlwm ntawm kev cob lub luag haujlwm: CO thiab Fes rau cov pab hloov pauv cov ntsiab lus, thiab ntau yam ntxwv zoo sib xws.CA daim foos Carbide Co ₂ C nrog pob zeb diamond nyob rau hauv cov xwm txheej tshwj xeeb, thaum tseem kis tau tus nqi sib tw uas tsis muaj pob zeb diamond.Nyob rau hauv txoj kev no, cow tuaj yeem txo cov sab hauv sab hauv nruab nrab ntawm co thiab pob zeb diamond, thiab muaj cov nplaum tseem ceeb ua haujlwm rau lub tawb ua haujlwm, ua nws cov khoom siv ua kom zoo.

Lub luag hauj lwm ntawm Nickel: nyob rau hauv phau ntawv binder ntawm pob zeb diamond cov cuab yeej, NI yog qhov tseem ceeb indispensable.Hauv CU raws li alloys, ntxiv rau Ni tuaj yeem ua rau muaj kev sib ntxiv nrog CU, txhim kho kev ua haujlwm me me, thiab nce saws thiab hnav kev tiv thaiv.Ntxiv NI thiab CU rau FE ALOYS tuaj yeem txo cov sintering kub thiab txo cov thermal corrosion ntawm cov hlau ua hlau ntawm pob zeb.Xaiv qhov tsim nyog ua ke ntawm FE thiab NI tuaj yeem txhim kho lub zog tuav ntawm Fe raws burners ntawm pob zeb diamond.

Lub luag haujlwm ntawm manganese: hauv cov hlau khi hlau, manganese muaj cov nyhoo zoo sib xws rau cov hlau, tab sis muaj kev muaj zog thiab muaj peev xwm ua rau oxidation.Qhov kev sib ntxiv ntawm MN feem ntau tsis siab, thiab kev txiav txim siab tseem ceeb yog siv mn rau deoxidation thaum sintering aloying.Qhov seem MN tuaj yeem koom nrog kev sib dhos thiab ntxiv dag zog rau lub matrix.

Lub luag haujlwm ntawm chromium: Hlau chromium yog lub zog carbide-acing keeb thiab kuj tau siv cov khoom siv dav.Nyob rau hauv lub pob zeb diamond groove sawix, muaj txaus chromium txaus chromium txaus cov nyhuv zoo, uas yog cuam tshuam rau kev ua kom muaj zog ntawm Cr.Ntxiv ib qho me me ntawm CR rau CU raws li CU raws li lub tsev loj tuaj yeem txo lub zog ntub dej ntawm lub taub hau tooj liab ntawm lub tooj liab raws li pob zeb diamond.

Lub luag haujlwm ntawm Titanium yog lub zog carbide sib sau keeb uas yooj yim rau oxidize thiab nyuaj kom txo.Nyob rau hauv lub xub ntiag ntawm cov pa, ti xum generates tii2 hloov tic.Titanium hlau yog cov txheej txheem zoo nrog muaj zog, tsawg dua lub zog tiv thaiv, kub tsis kam, thiab siab yaj taw tes.Kev tshawb fawb tau pom tias ntxiv tus nqi tsim nyog ntawm titanium rau lub pob zeb diamond pom lub pob zeb diamond pompix muaj txiaj ntsig rau kev txhim kho lub neej kev pabcuam.

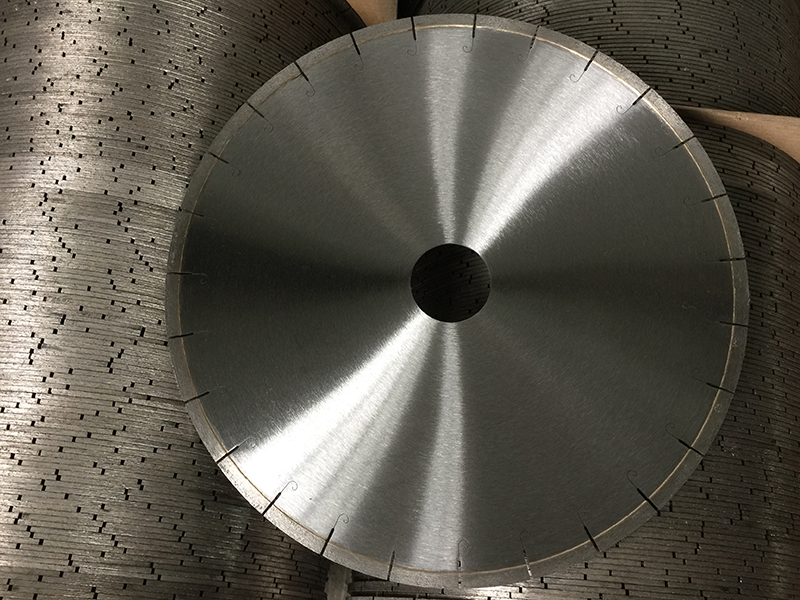

2.Vim li cas cov saw hniav yuav tsum phim lub pob zeb txiav?

Cov txheej txheem ntawm pob zeb tawg thaum pom cov hniav txiav yog pob txha lov thiab crushing, nrog rau cov ntim loj shear thiab tawg, ntxiv los ntawm kev sib tsoo saum npoo.Lub pob zeb diamond nrog cov ua haujlwm ntawm cov haujlwm ua haujlwm uas ua haujlwm ua cov cuab yeej txiav.Nws txiav ntug yog qhov chaw extrusion, qhov chaw txiav yog nyob rau hauv pem hauv ntej ntawm ntug, thiab thaj chaw sib tsoo yog nyob sab nraub qaum.Nyob rau hauv kev txiav ceev, pob zeb diamond hais ua haujlwm ntawm kev txhawb nqa ntawm matrix.Thaum lub sij hawm cov txheej txheem ntawm txiav pob zeb, ntawm ib sab tes, pob zeb diamond incegoes graphitization, thiab detachment vim muaj kub kub los ntawm kev sib txhuam;Ntawm qhov tod tes, lub matrix hnav hnav los ntawm kev sib txhuam thiab yaig ntawm pob zeb thiab cov hmoov pob zeb.Yog li no, qhov teeb meem ntawm kev yoog raws li cov hniav thiab cov pob zeb yog qhov tseeb qhov teeb meem ntawm hnav tus nqi ntawm pob zeb diamond thiab matrix.Cov yam ntxwv ntawm cov cuab yeej uas ua haujlwm ib txwm yog tias qhov ploj ntawm pob zeb diamond sib tsoo, ua kom lub tsev ua haujlwm sib tsoo, kom tau cov nyhuv uas nws cov nyhuv sib tsoo Thaum lub sijhawm ua haujlwm, uas ua rau ntau lub pob zeb diamond tau nyob hauv ib qho kev sib tsoo me ntsis thiab lub xeev hnav.Yog tias lub zog thiab cuam tshuam tsis tau ntawm lub pob zeb diamond xaiv tau tsawg, nws yuav ua rau cov txiaj ntsig ntawm ", thiab lub cuab tam", thiab lub sijhawm uas passivation yuav loj, thiab txawm tias tus uas pom yuav tsiv mus;Yog tias kev vam meej siab ntau dhau lawm tau xaiv, kev txiav ntawm cov abrasive uas tau tshwm sim hauv kev txiav tawm hauv lub xeev

(1) Thaum hnav ceev ntawm lub matrix loj dua li ntawm lub pob zeb diamond, nws ua rau ntau lub pob zeb diamond ntau dhau thiab pib ua haujlwm.Cov coj tsis kam ntawm lub hau hniav lub cev yog tsawg heev, thiab lub ntsej plaub lub neej yog luv.

(2) Thaum hnav ceev ntawm lub matrix tsawg dua li ntawm lub pob zeb diamond, lub ciamond txiav yooj yim, cov serrations tsis muaj qhov txiav yog qhov tsawg heev, lub npoo ntawm Cov serrations yog passivated, kev txiav ceev yog qeeb, thiab nws yog ib qho yooj yim los ua rau lub rooj tsav tsheb txiav tawm, cuam tshuam rau kev ua haujlwm zoo.

(3) Thaum hnav ceev ntawm lub matrix yog sib npaug zos rau kev coj ceev ntawm lub pob zeb diamond, nws qhia txog kev sib raug zoo ntawm cov matrix nrog txiav pob zeb txiav.

Lub Sijhawm Post: Lub Yim Hli 11-2023