1.Kuaj xyuas lub puab thiab sab hauv txoj kab uas hla ntawm cov hniav, thickness thiab tus naj npawb ntawm cov hniav ntawm lub substrate raws li qhov yuav tsum tau ntau lawm, thiab xyuas cov specification, kom muaj nuj nqis thiab radian ntawm lub pob zeb diamond ntu.Tom qab ntawd grind lub txheej chamfer ntawm lub substrate ntawm cov khoom hnav khaub ncaws.Ntxuav lub vuam nto ntawm lub hauv paus thiab ntu nrog C hloov, thiab siv tus neeg sawv cev soldering.

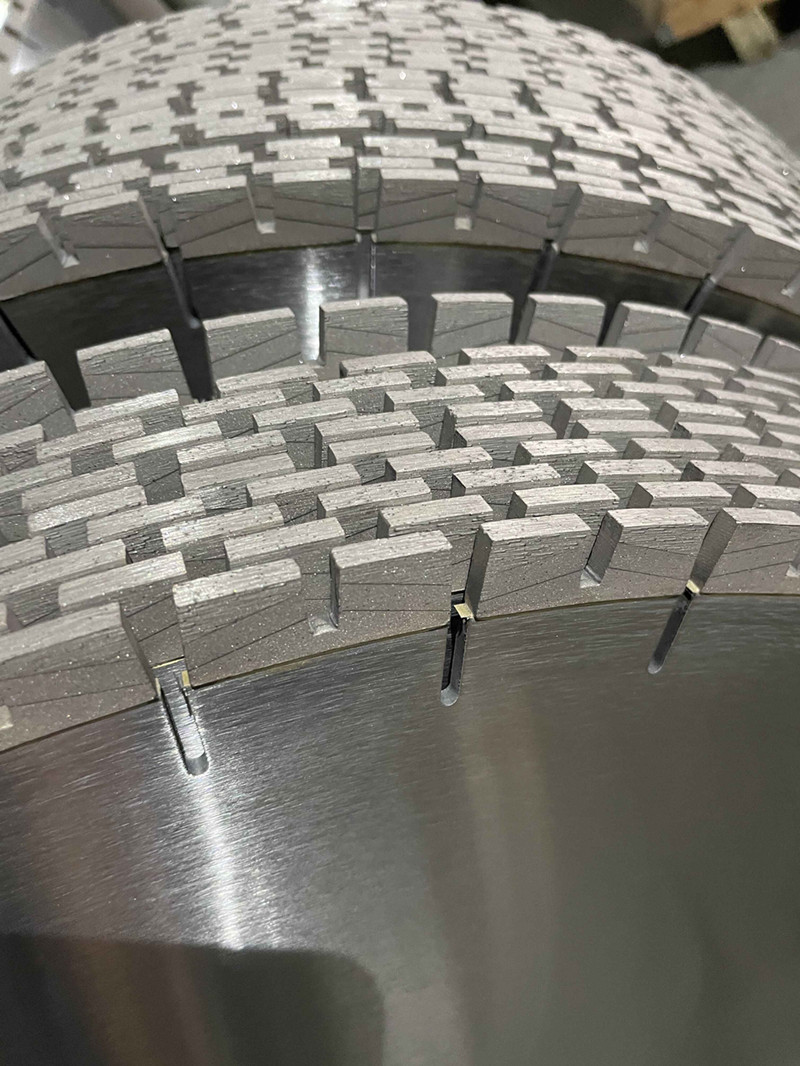

2.Xaiv qhov tsim nyog vuam hniav raws li cov saw hniav specification hauv kev tsim kho.Qhov dav ntawm vuam hniav feem ntau yog 0 ntau dua li lub hauv paus thickness.Lub thickness ntawm vuam hniav yuav tsum yog 0.25-0.30mm thaum vuam cov saw hniav nrog ib txoj kab uas hla ntawm 5-1 hli thiab ntau tshaj 1500 hli;Thaum vuam cov saw hniav nrog txoj kab uas hla tsawg dua 1500mm, lub thickness ntawm vuam hniav yuav tsum yog 0.15 ~ 0.25mm.

3.Install lub hauv paus, kho txoj hauj lwm, zawm lub fixing screws, muab tso rau hauv lub txias splint, kho segment pushing ntaus ntawv thiab segment clamp, kho qhov vuam kub, txuag tshav kub thiab txias lub sij hawm raws li tus txheej txheem yuav tsum tau, thiab nqa tawm. vuam.

4.Thaum welding cov saw hniav nrog cov khoom siv high-frequency, tig lub hauv paus 180 ° C rau txhua ntu welded, thiaj li weld symmetrically kom tsis txhob annealing lossis hauv zos deformation tshwm sim los ntawm overheating ntawm lub hauv paus.

5.Thaum vuam cov laib pom hniav, vuam ntu mus rau qhov chaw teev tseg raws li cov hniav layout.

6. Tom qab welding ib tug saw saw, yuav tsum tau ua nws tus kheej soj ntsuam.

Post lub sij hawm: Mar-04-2023